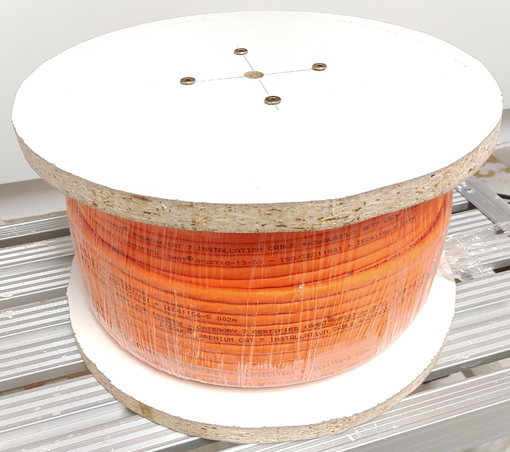

A sleeve for OD125 wastewater pipes happened to be the perfect size for this particular cable. It has a smooth outer surface so the cable won't be damaged even if it slides on the inside of the reel.

The side walls were cut out from 16mm particle board using a jigsaw. They are screwed onto four sections of wood slats, cut to match the length of the pipe sleeve.

The design works quite well so far (better than expected in fact). 🤩

2/2