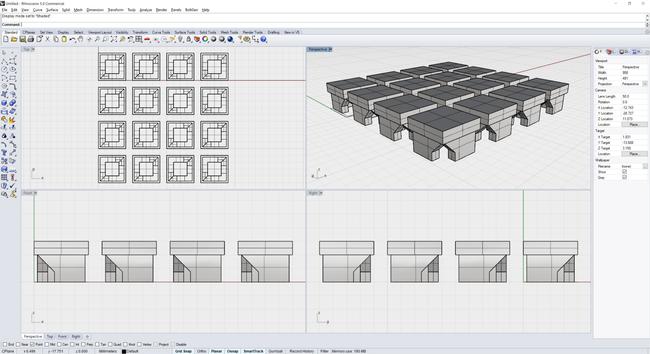

Ok, interesting #CGAPrints / #Thrixels update today. The last few colours - brown, grey and dark green - have come out with noticeably crap quality, probably my printer needs some preventative maintenance after churning out thousands of the same part, but also I should probably build in more tolerance because different filaments are going to act differently.

I'll keep building this stockpile for early pixel art tests, but might revise for time investments in bigger projects. #3DPrinting