How To Build A Turbo Car The Cheap, 90s Way

If you want to coax more power out of your car's engine, a turbocharger is a great way to go about it. Taking waste energy from the exhaust and using it to cram more air into the engine, they're one of the best value ways to make big gains in horsepower.

However, unlike simpler mods like a bigger exhaust or a mild cam swap, a turbocharger install on a naturally aspirated, fuel-injected engine often requires a complete replacement of the engine management system, particularly on older cars. This isn't cheap, leaving many to stick to turbocharging cars with factory tuneable ECUs, or to give up altogether. In the 1990s, aftermarket ECUs were even more expensive, leading many to avoid them altogether. Instead, enthusiasts used creative hacks to make their turbo builds a reality on the cheap, and there's little stopping you from doing the very same today.

Fuel and Timing

The best solution is to use an aftermarket ECU for full control over fuel and timing, but this can be cost prohibitive.

The reason a turbocharger install typically necessitates an engine management overhaul is due to the need to vastly change the engine's fuel and timing map. A stock, naturally aspirated (NA) engine with fuel injection can measure the incoming airflow and load on the engine, and uses this information to determine the correct amount of fuel to inject and when to fire the sparkplugs. However, with a turbocharger installed, the pressure in the intake, which is usually below atmospheric pressure for an NA engine, becomes positive under boosted conditions, and this can completely confuse a stock ECU. At best, it reverts to an "open loop" control method, ignoring its pressure or airflow readings into the engine. This uses a base table to decide how much fuel to inject and when to fire the ignition, based on engine RPM and throttle position only. With the turbocharger forcing much more air into the engine than expected by the ECU, the air/fuel ratio will be severely lean, likely leading to detonation, in which the air/fuel charge in the cylinder detonates instead of burning at a smooth constant rate. This can damage or destroy an engine in short order.

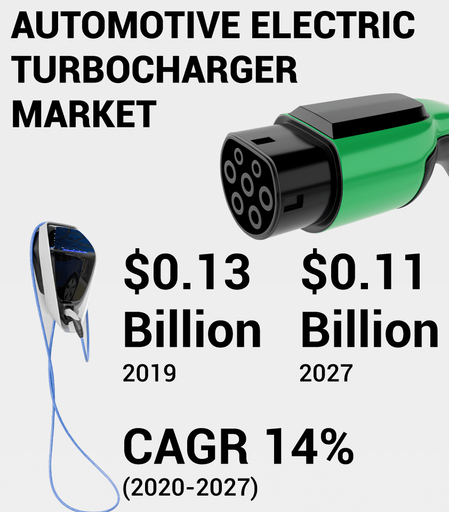

A typical rising rate fuel pressure regulator. The two ports on the back are the fuel inlet and outlet, while the port on the front is the boost reference, connected to the intake manifold.

Thus, to properly run a turbocharger on a formerly naturally aspirated car, it's necessary to inject more fuel to match the added air forced into the intake. This is where the power gains come from, after all. The best way to do this is by using a custom ECU that allows full control over the fuel and timing maps. This allows the engine to be tuned to deliver optimum performance right up against the limits of detonation and damage, and provides solid, repeatable performance. However, there are other more rudimentary ways to get the job done -- increasing fuel flow and controlling timing -- without going to the trouble of a full ECU replacement.

Fuel-wise, the cheap, low-tech solution is known as a rising-rate fuel regulator. Such a regulator increases the pressure in the fuel rail in proportion with the boost level. This is often done at a ratio -- for example, a 10:1 rising rate regulator will deliver an extra 10psi of fuel pressure for every 1 psi of boost. The higher pressure causes the injectors to deliver more fuel for the same duty cycle. This makes it possible to increase fuel flow into the engine as the turbocharger spools up and delivers boost without having to make any changes to the fuel map in the stock ECU. These devices can be had cheaply, often with a variety of swappable diaphragms to change the ratio and tune the fuel delivery somewhat, though with far less finesse than a properly tuned fuel map.

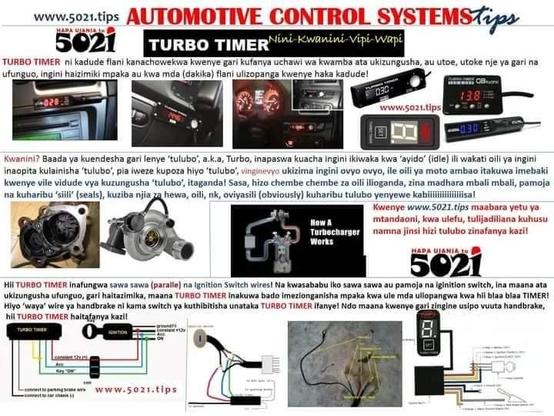

The Apexi Super-ITC was a popular ignition timing controller from the 1990s. The high cost of aftermarket ECUs in this time period led to the popularity of such "piggyback" solutions.

Timing-wise, there are a few options available to avoid detonation. On cars where such adjustment is available, the cheapest method is to simply wind down the base timing of the engine to a lower level. This will keep timing lower across the board, hopefully avoiding detonation when running at high RPM and high boost levels. However, this means that at lower RPM and lower load situations, the car will be running with suboptimal timing, and will sacrifice power and drivability and likely cause the engine to idle poorly. This can be acceptable for cheap race builds, but may be frustrating for a street driven car. Alternatively, a timing box, or ignition timing controller, can be wired into the car. These consist of a microcontroller that monitors signals like intake air temperature, RPM, engine position and boost. When the timing box detects boost, it intercepts signals from engine position sensors and spoofs them back to the ECU, offset so as to change the time at which the ECU triggers the ignition pulses. Popular models include the Bipes ACU for the Mazda Miata, and the Apexi S-ITC for a broad spectrum of JDM cars. Often, these timing boxes were also used to tune turbocharged cars running larger turbos and other major upgrades. Timing boxes usually offer some degree of tuning via DIP switches, LED displays, and knobs, which can be set to determine the exact level of timing retard desired to keep the engine out of detonation.

ECU Swaps Have Become the Preferred Hack

One thing you'll notice when researching these devices is that the vast majority of forum posts regarding the technology date from before 2005. This is because as technology has progressed, aftermarket ECUs have come down in price enough to make them a more attractive option. The capability to properly dial in a fuel and timing map, versus trying to push and prod a stock ECU into delivering huge amounts of extra fuel and less timing, generally leads to a car that drives smoother, more reliably, and is less likely to blow up. It also is a lot easier to tune. However, these parts still have a place in the scene. They're used for the absolute lowest-budget builds, such as the Broke and Boosted project, or in racing series like the 24 Hours of Lemons which feature restrictive budget limits. These techniques are also relevant to supercharging NA engines, as well as turbo builds on carburetted engines, though substituting rising rate regulators for boost-referenced carburettors and timing interceptors for boost-ready ignition systems.

A modern engine management system may be the most reliable, accurate way to tune a boosted engine, but it's not the only way. However, don't expect to get much help from the broader automotive community if you attempt such a build. The tricks and techniques have largely been consigned to the dustbin of history, so you may find yourself poring over old manuals and having to troubleshoot blind. But if money, racing regulations, or simply the sheer thrill of doing things the old fashioned way put you in that situation, we hope this guide gives you the best possible shot at success. Good luck, and happy wrenching!

#carhacks #featured #automotive #car #cars #fuelinjection #turbo #turbocharger