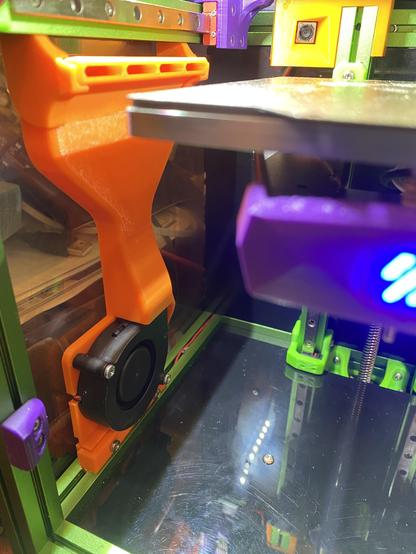

Another mod fitted to my Voron 0.2

Bed blower fan to assist cooling of faster PLA prints.

#3dprinting #voron #OpenSource

#Voron

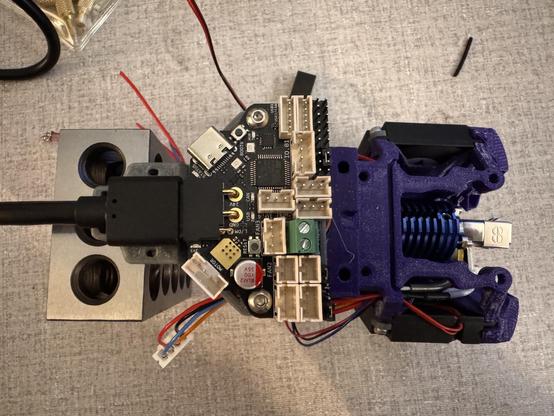

I forget the #Voron approved designs are awesome. I had ordered a BTT board for my stealth burner, but as I tried to put it on, I realize so many of the connections are different. I should probably re-pin my heater too. I ended up using K. Hart’s two PCB design instead. So much simpler to adapt from my old wiring. I may use the BTT on my switch wire.

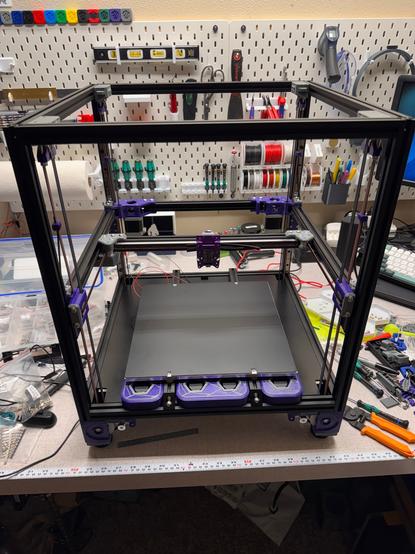

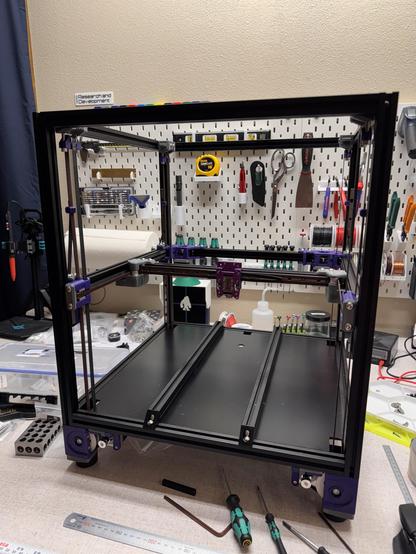

The 3D printer arrived yesterday. Hopefully will find some time over the weekend to put it together. First thought, I have sit with my kids on some History and Mathematics.

Funny how I'm already thinking of the upgrades I would like to do, even before putting it together.

Description complète kit Formbot Voron 2.4 - Voron - Forum pour les imprimantes 3D et l'impression 3D https://www.lesimprimantes3d.fr/forum/topic/53116-description-compl%C3%A8te-kit-formbot-voron-24/ #3dprint #voron #diy

Don’t yet have a replacement for my unflashed H36. I got an ST Link in the mail and am going to try and solder on a couple leads to flash it myself.

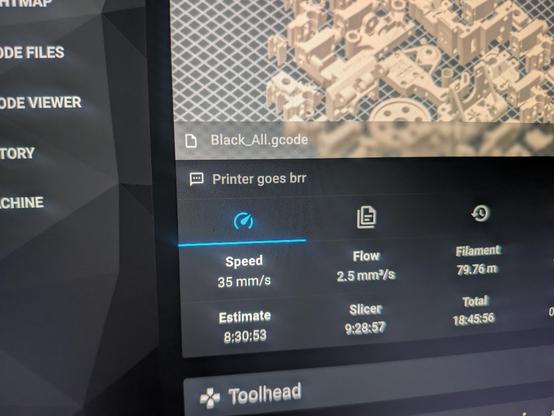

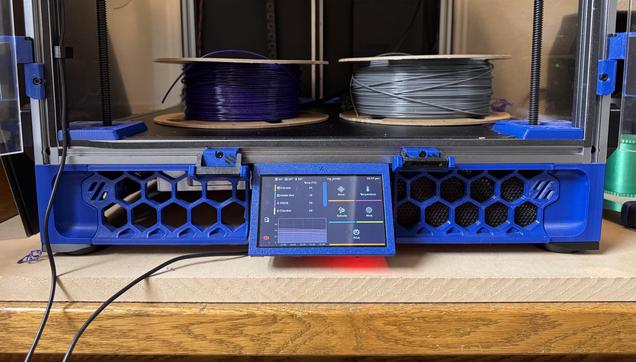

In the mean time I installed the skirts and the touch screen. I think it’s looking great. Certainly looks nearly complete.

🧵13/

Now with a #Voron, you're probably missing 20-40% of the instructions you need (or they're out of order, or just different), but the most annoying thing was getting all the belts on the toolhead carriage, which in comparison wasn't even that bad. #Prusa #PrusaMk4S #3DPrinting

Still having issues with my fysetc H36 toolhead board.

All the rest of the electronics are done and everything is wired up. Trying to work with the vendor on a replacement board and stuck until then.

Got #klipperscreen running easily and had nothing much to do after that.

Decided to work on skirts to keep some traction going.

Layer 1 of 100…

🧵12/

I haven't yet had to hold 4 separate sets of instructions in my head, so that's cool.

With the #Voron, it turned out the printed Voron instructions I bought were slightly out of date, then LDO had its own modifications. Which I unintentionally followed old documentation for. That was fucking obnoxious. #Prusa #PrusaMk4S #3DPrinting

Small printer problems: can't run a flow calibration test in one go. #3DPrinting #Voron

Trimmed the PTFE tube and the #Voron V0 is in its place. Some of these panel brackets are not looking great, particularly on the door. I finished this printer in January (?) and literally used it once. #3DPrinting

Toolhead mounted.

I went with a fairly standard Xol setup.

- BOM Delta fan for the hot end.

- 24V 4010 for part cooling

- Rapido 2 HF hot end

- Sherpa mini extruder

- Fysetc H36 toolhead board

Mounted easily to the Vitalii TAP carriage, then a whole lot of crimping to get everything connected.

🧵11/

My hope is that even though it'll need more hands-on tweaking than a proprietary printer, it can still be more of a tool than a project (and for a longer time).

(Although my personal history of owning 3d printers suitable for workshop tools is 0/2 to date, so highly skeptical of my own judgement on this.)

I have the opportunity to buy a mate's Voron V2.4 3D printer. It's a hobbyist self-sourced build completed a few years ago, but done carefully and with good parts (LDO motors, reputable extrusions, etc).

Anyone know what common issues I should be looking out for? Belt tension & idlers seems to be the most common weak point, from what I've read so far.

The Filters wired, and bed installed. Pretty straight-forward stuff. Continuing to look more and more "printer-like"

As I'm skipping the magnetic pogo connector for The Filters, I'm also skipping the mount for the center filter and just have a couple bolts acting as backstops to prevent over-insertion.

🧵10/

Electronics folks, I’m looking for an easy to use connector that I can use for installing a filtration unit under the bed of my voron 2.4 printer.

It’s going to be in an airspace between a 110C heater and an ACM deck plate so it will likely be quite warm but not oven hot.

Something like a barrel jack would be great but the ones I see on DigiKey and McMaster are only rated at 80C.

What’s a better option? Just a JST?

I really like the chamber heating advantages that bed fans have in my trident so for this build I want the same effect.

I’m going to try “The Filter” and see if it can offer me the same benefit along with replacing my nevermore/bento setups in the trident.

Going to skip the unusual magnet/pogo connector and just use something manual and standard instead. Maybe just a barrel jack.

🧵9/

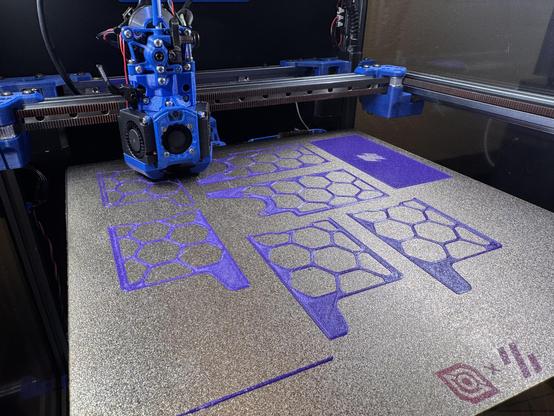

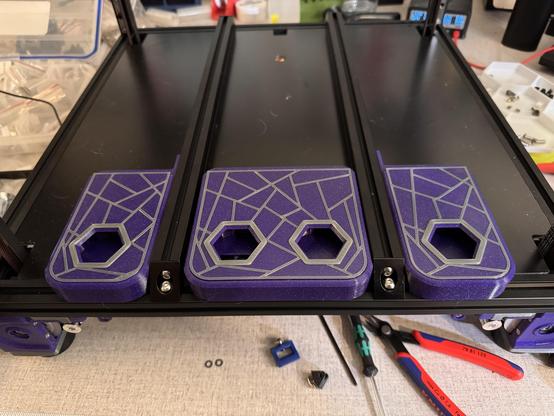

I was printing bits for the electronics bay on the 2.4 and had a small diversion.

I printed the snap in mesh skirt inserts for my trident.

The stock skirts are so open they just look unfinished to me. These are a small addition but they make things look a lot tidier and more complete.

This is going to be the plan for the 2.4 as well.

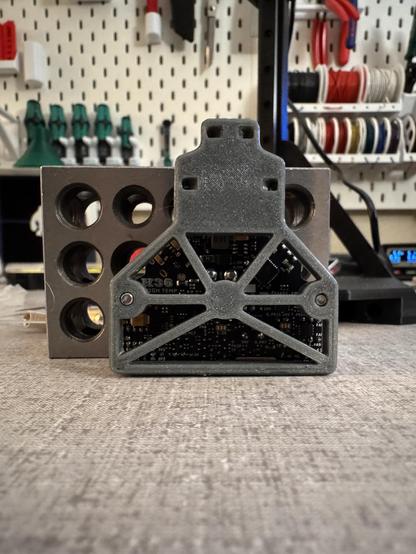

Time to attach the toolhead board.

I am using the Fysetc H36 which has a nice high temperature rated chipset, fan tach pins, and variable fan voltages which makes it play super nice with a Xol toolhead.

It also comes with a pretty nice umbilical cable with an over molded connector.

I remixed a mount that @koz was working on and came up with this in #FreeCAD.

Seems to fit pretty well, clears everything, gives some strain relief to the soldered connector, and should keep the molded cable in place as there is no positive retention clip.

🧵8/

Alright. Fully belted, tensioned, and de-racked.

I also assembled my Vitalii3D MetalTap, it seems to work ok and have a much more solid hold than the chaotic labs v2 tap on my Trident. I’m curious to see the performance once I get this machine up and running.

🧵7/