Mining and Refining: Titanium, Our Youngest Industrial Metal https://hackaday.com/2023/12/05/mining-and-refining-titanium-our-youngest-industrial-metal/ #vacuumarcremelting #MiningandRefining #Engineering #OriginalArt #magnesium #reduction #Featured #titanium

#miningandrefining

Mining and Refining: Copper, the Metal That Built Technology

It's hard to reckon exactly when in history humans became a technological species. Part of that is because the definition of technology is somewhat subjective; if you think making a stick pointy enough to grub roots from the dirt or to poke enough holes in an animal to convince it to let you eat it is technology, then our engineered world goes back a long, long way indeed.

But something about pointy sticks just doesn't seem transformative enough, in the sense of fundamentally changing a naturally occurring material, to really count as a technological line in the sand. To cross that line, it really seems like the use of metals should be part of the package. Even if that's the case, our technological history still goes pretty far back. And copper ends up being one of the metals that started it all, about 11,000 years ago, when our ancestors discovered natural deposits of the soft, reddish metal and began learning how to fashion it into the tools and implements that lifted us out of the Stone Age.

Our world literally cannot run without copper, forming as it does not only the electric-motor muscles of civilization, but also the wires and cables that form the power and data grids that stitch us together. Ironically, we are just as dependent on copper now as we were when it was the only metal we could make tools from, and perhaps more so. We'll take a look at what's involved in extracting and purifying copper, and see how the methods we today use are not entirely different from those developed over seven millennia ago.

Shiny Rocks

As useful as copper was to early civilizations, and for as easily accessible as it was thanks to surface deposits of native copper sprinkled around the world, it was not the first metal to be discovered and worked. That honor falls to both gold and, strangely enough, meteoric iron. But neither of these metals was abundant enough to make anything but a token impact on technology, and mostly ended up enriching and ornamenting kings and princes.

Copper, however, was easily located and, perhaps more importantly, easily worked without the need to develop much infrastructure -- at least at first. Lumps of copper could be pried from native copper deposits and cold-worked with stone tools into useful artifacts, thanks to copper's malleability. It wasn't long before copper's relatively low melting point led to the discovery of casting, which led to more uses for the metal and increased demand.

You can practically see the copper in chalcopyrite. Source: Rob Lavinsky, via Wikimedia Commons (CC-BY-SA 3.0)

Eventually, supplies of native metal from easily exploited deposits exceeded demand, and our ancestors discovered smelting from various copper-bearing ores. The most important ore for commercial copper production is called chalcopyrite, an iron-containing copper sulfide mineral with the chemical formula CuFeS2. Chalcopyrite deposits are found all over the world, with particular abundance in North and South America, as well as Africa and Australia. Other important ores occur as oxides and carbonates of copper, like azurite and cuprite.

Although some deep-shaft mining is done, most of the big copper mining operations are vast open-pit mines. The world's most productive copper mine right now is the Minera Escondida in the Atacama Desert in Chile, which produced $10 billion worth of copper in 2007 and can output 1.2 million tons a year. While a pure sample of chalcopyrite is about 34% copper by weight, the mineral is usually associated with a host rock species that reduces the ore to a fraction of a percent of copper. This means that vast amounts of ore have to be processed to make a mining operation commercially viable. In some deposits, gold and silver are sparingly substituted for copper in the ore, making these precious metals a valuable side product that in some cases can actually pay for the entire cost of extraction of all the copper.

Extraction in open-pit mines begins with typical hard-rock mining methods, like blasting. Ore-bearing rock is loaded 200 to 300 tonnes at a time by enormous loaders and shovels into mammoth haul trucks, for the trip up out of the pit to the processing plant. There, enormous crushers reduce the car-sized boulders into smaller and smaller fractions, which are passed to ball mils for finer grinding. The goal is to reduce the physical contact between the ore minerals and the waste rock that surrounds it, which is called gangue.

What happens next is the extraction of the elemental copper from the ore minerals, but the method used depends upon which type of ore is present. For oxides and carbonates of copper, the copper is soluble in acid solutions, so a hydrometallurgical process is used. Details vary, but in leaching processes, typically the powdered ore is piled up in large pits lined with an impervious barrier. Dilute sulfuric acid is sprayed onto the piles and leaches copper sulfate from the ore minerals. The copper is stripped from the leachate with special extractants , which leaves the sulfuric acid clean and ready to be recycled for another round of leaching, plus a copper-rich solution ready for further purification.

Heap leaching schematic. Piles of ore are sprinkled with sulfuric acid; the copper-laden leachate is collected and concentrated. Source: University of Arizona Superfund Research Center

Floating to the Top

Copper sulfide ores are at a disadvantage when it comes to chemical methods of extraction, since the sulfides are barely soluble in acid. To free copper from these ores, refiners need to turn up the heat with pyrometallurgical methods. These begin with the same crushing and grinding steps as before, resulting in a fine powder that is mixed with water in large vats. To the slurry are added chemicals known as collectors , whose job it is to bind to the sulfide mineral particles. The collector molecules cover the sulfide particles and increase their hydrophobicity, or tendency to repel water, while leaving the waste rock particles alone. When air is bubbled through the solution, the now-hydrophobic sulfides attach to the air bubbles and form a froth at the surface of the vat, which is skimmed off the top and subjected to further rounds of this froth flotation method to increase the concentration of copper.

The output from this froth flotation process is then put through a thickening process, to remove as much water as possible. This is done by a combination of simple evaporation in open ponds, and by filtration using porous ceramic discs or cylinders. The filtration step is critical, as it lowers the moisture content to around 8% and results in a copper concentrate of about 20-30% enrichment that can be easily shipped to smelting plants.

Cross-section of a flash smelter. Ore concentrate melts in the superheated air blast in the reaction chamber, and matte copper collects at the bottom for tapping. Source: Jylhä et al , MDPI (CC-BY-4.0)

To extract the copper from the concentrate, a flash smelting process is used. Concentrate is sprayed into a reaction column in a flash furnace along with heated, oxygen-enriched air. The sulfide compounds in the concentrate melt instantly and fall to a collecting pool at the bottom of the furnace. There, the molten materials separate by density, with the molten copper, called matte copper , sinking to the bottom, while the iron and silicate slag floats to the top with the assistance of added fluxes.

Matte copper, now about 60% pure, is tapped off the bottom of the flash furnace for further purification through conversion, which is basically blowing hot air through the molten matte. The oxygen reacts with the remaining sulfur, leaving behind blister copper that's about 98% pure.

Winning with Electricity

The final stage of purification for the end products of both hydrometallurgical and pyrometallurgical extraction is called electrowinning. This is simply electrolysis, albeit on a massive scale. For hydrometallurgical copper, the copper sulfate solution that comes from the leaching pit is used as the electrolyte, with lead anodes and thin stainless steel sheets for cathodes. Current is passed through the electrolyte, causing the copper in the solution to plate out onto the stainless steel cathodes. When about 100 pounds (45 kg) of copper have accumulated on the cathodes, they are removed, rinsed, and flexed to pop off the finished, 99.99% pure copper sheets.

For pyrometallurgical copper, the blister copper ingots serve as anodes for electrowinning. They are suspended in a tank filled with dilute copper sulfate mixed with sulfuric acid, interleaved with cathodes of either pure copper sheets or, again, stainless steel. Current is passed through the tank and the copper plates out on the cathodes, again reaching 99.99% purity in the finished process.

The waste product left behind in the electrowinning tanks is known as anode slime , and despite its unappealing name is a valuable product. Depending on the minerals present in the feedstock and the voltage used for electrowinning, the anode slime can contain gold, silver, selenium, tellurium, and possibly even platinum-group metals, along with a fair amount of copper that wasn't recovered in the first go-around. Anode slime is generally sold off to specialty smelters for recovery of these valuable metals, using combinations of hydrometallurgical and pyrometallurgical processes that are customized to the blend of metals in the slime.

Banner image: "Native copper-replaced cross-bedded sedimentary rocks" by James St. John, CC BY 2.0

Mining and Refining: Pure Silicon and the Incredible Effort It Takes to Get There

Were it not for the thin sheath of water and carbon-based life covering it, our home planet would perhaps be best known as the "Silicon World." More than a quarter of the mass of the Earth's crust is silicon, and together with oxygen, the silicate minerals form about 90% of the thin shell of rock that floats on the Earth's mantle. Silicon is the bedrock of our world, and it's literally as common as dirt.

But just because we have a lot of it doesn't mean we have much of it in its pure form. And it's only in its purest form that silicon becomes the stuff that brought our world into the Information Age. Elemental silicon is very rare, though, and so getting appreciable amounts of the metalloid that's pure enough to be useful requires some pretty energy- and resource-intensive mining and refining operations. These operations use some pretty interesting chemistry and a few neat tricks, and when scaled up to industrial levels, they pose unique challenges that require some pretty clever engineering to deal with.

Hard as Rock

The raw material for most silicon production is the mineral quartzite. Quartzite comes from ancient deposits of quartz sands that formed sedimentary deposits. Over time and with heat and pressure, these quartz sandstones were transformed into the metamorphic rock quartzite, which is at least 80% quartz by volume.

Quartzite. Source: Geology.com

Quartzite is an incredibly tough rock, and where it pokes above the surface, it forms ridges that strongly resist weathering. Significant formations of quartzite are scattered all around the world, but there are relatively few places where it makes financial sense to quarry the rock for silicon production, since the formations need to be easily accessible and relatively close to the other raw materials and energy supply needed.

Raw quartzite is mostly silicon dioxide (SiO2), and the refining process begins with a reduction reaction to get rid of the oxygen. Crushed quartzite is mixed with carbon in the form of coke (coal that has been heated in the absence of oxygen). Woodchips are added to the charge as well; they serve both as a carbon source and a physical bulking agent that allows gasses and heat to circulate better in the furnace.

The arc furnaces for silicon smelting are massive installations with huge carbon electrodes. The electrodes are consumed during smelting, so new electrodes are screwed onto the tops of the current electrodes to make sure the process isn't interrupted. The arc furnace requires massive amounts of electricity to maintain the 2,000°C temperature needed, so silicon refineries are often located where electricity is cheap and plentiful.

The reduction reactions inside the melt zone are actually pretty complicated, but can be summed up with two main reactions:

In both reactions, the oxygen in the silicon dioxide combines with carbon to form the main waste product, carbon monoxide. A side reaction that occurs in a part of the melt zone inside the furnace produces silicon carbide (SiC), which is an unwanted byproduct (at least when the goal is to purify silicon; silicon carbide itself is a useful industrial abrasive). By making sure that silicon dioxide is far in excess in the furnace, the second reaction where the SiC acts as a carbon source for the reduction of silicon dioxide is favored, and silicon with up to 99% purity can be tapped off the bottom of the furnace.

The silicon produced by this process is referred to as metallurgical silicon. For almost all industrial uses, this highly purified silicon is good enough. About 70% of metallurgical silicon goes to the manufacture of metal alloys such as ferrosilicon as well as aluminum-silicon, an alloy that contracts minimally upon cooling and is therefore used to cast aluminum engine blocks and similar items.

More Nines

Monosilane is the silicon equivalent of methane. In trichlorosilane, three of the hydrogens are substituted for chlorines. Source: WebElements

As useful as metallurgical silicon is, even at 99% pure it's not even close to the purity needed for semiconductor and photovoltaic applications. The next steps in purification take the silicon to the purity level that's needed for semiconductor manufacture. Purification starts by mixing powdered metallurgical silicon with hot, gaseous hydrochloric acid. This reaction produces silanes, which are compounds with a central silicon atom surrounded by four attachments, in this case three chlorine atoms and one hydrogen. This trichlorosilane is a gas at the temperature inside the reaction chamber, which makes it easier to handle and purify by fractional distillation.

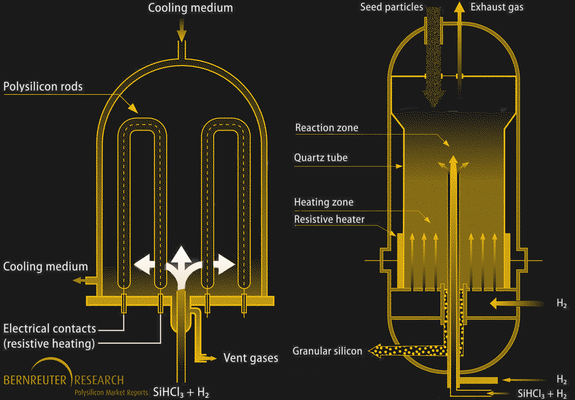

When the trichlorosilane gas has been sufficiently purified, polycrystalline silicon production can begin. The Siemens process is the main method here, and is a form of chemical vapor deposition. A large bell-shaped reaction chamber contains several thin threads of highly purified silicon, which are heated to 1,150°C by passing an electric current through them. A mixture of gaseous trichlorosilane and hydrogen flows into the chamber; the gas decomposes on the hot electrode leaving behind the silicon, which accretes into rods that are about 15 cm in diameter. Polycrystalline silicon made by the Siemens process can have a purity of 99.99999% ("seven nines", or 7N) or more. 7N to 10N polysilicon is mostly used for photovoltaic cells, although some polysilicon in this purity range also makes it into MOSFET and CMOS semiconductors.

Polysilicon rods from a Siemens process chamber. Source: Silicon Products Group GmbH

While the Siemens process is the polysilicon workhorse, it has its disadvantages. The main problem is that it's an energy hog -- keeping the growing polycrystalline rods hot enough to decompose the feedstock requires a lot of electricity. To work around this problem, a fluidized bed reactor (FBR) process is sometimes used. An FBR reactor is shaped like a tall tower, the walls of which are lined with a quartz tube. Silane gas, either the familiar trichlorosilane or monosilane, which is just a silicon atom surrounded by four hydrogens, is injected into the chamber. Powdered silicon is dropped into the reaction chamber from the top, while heated hydrogen gas is injected into the bottom of the chamber through a series of nozzles. The gas flow keeps the hot silicon powder fluidized, allowing it to mix with the silane gas and decompose it. As in the Siemens process, the silicon accretes onto the seed particles, which eventually get too large for the fluidized bed to support. The polycrystalline silicon beads drop to the bottom of the chamber, where they can be collected.

Aside from power savings -- up to 90% less when using monosilane as a feedstock -- the FBR method's main advantage is that it's a continuous process, since the finished beads can just be pumped out of the chamber. The Siemens process is more of a batch process, since the reactor chamber has to be opened to remove the polysilicon rods when they're finished. That said, FBR polysilicon hasn't really taken off, in part because managing the fluid dynamics inside the reaction chamber can be difficult. But the main reason is that the Siemens process is just so easy, and as long as factories can be located near a source of cheap electricity, it's just easier to use the brute-force method.

Polysilicon production by the Siemens process and fluidized bed reactor. Source: Bernreuter Research

One Crystal Only, Please

Using either of these methods, polycrystalline silicon can be brought to extremely high purity, up to 11N. But purity isn't the only metric for silicon; sometimes, the nature of the crystalline structure on the end product is just as important as purity. The next step in silicon production is the creation of monocrystalline silicon, where the entire silicon ingot is a single crystal.

Growing a single crystal of ultra-pure silicon to a size that's industrially useful is no mean feat, and relies on some tricks discovered in 1916 by Polish chemist Jan Czochralski. We've covered the Czochralski method in depth before, but briefly, polycrystalline silicon is melted in a quartz crucible in an inert atmosphere. A puller rod bearing a single ultra-pure silicon crystal that is very precisely oriented is lowered into the molten silicon. The seed crystal causes silicon to condense, continuing the crystal structure as the puller rod is slowly withdrawn from the furnace while rotating. Single-crystal ingots up to 450 mm in diameter are possible with the Czochralski method.

Another method to produce monocrystalline silicon is the float zone method, which uses a polycrystalline silicon rod as the starting material. Inside a reaction chamber with an inert gas atmosphere, a radio frequency signal is passed through a coil that surrounds the rod. The RF signal heats the polysilicon, creating a confined melt zone. Single crystals of ultra-pure silicon are added to the melt zone, which causes the molten silicon to crystallize around it. The RF coil is slowly moved up the rod, moving the zone of heating until the entire rod is a single crystal of silicon. Float-zone monocrystalline silicon has the advantage of never being in contact with the quartz walls of the Czochralski method crucible, and so will have less contamination from oxygen and other impurities.

#chemistryhacks #engineering #featured #originalart #science #crystal #metallurgy #miningandrefining #polysilicon #quartz #quartzite #silane #silicon #silicondioxide