@twilliability @fafo I am not sure we understand it either :D

FOR IMMEDIATE RELEASE

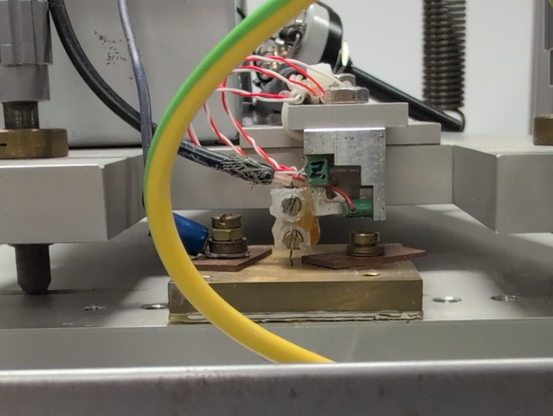

MUNICH (June 15th, 2025) - FAFO e.V. has announced today that it has successfully observed quantum tunneling effects between a tungsten probe (made with a pair of pliers) and a brass plate in a DIY scanning tunneling microscope that one of its members built a decade ago.

"Oh, we are tunneling!", exclaimed @rahix, lead Rust developer at FAFO, having never done this sort of work in his life before. "I think we can work with it", he claimed with full confidence.

@Crocmagnon @FreeCAD Are you looking for https://github.com/Rahix/FusedFilamentDesign ? ;)

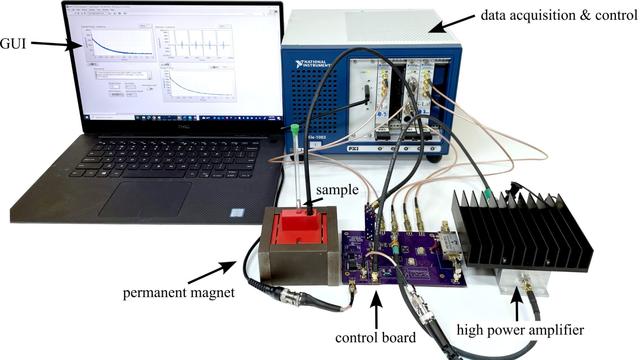

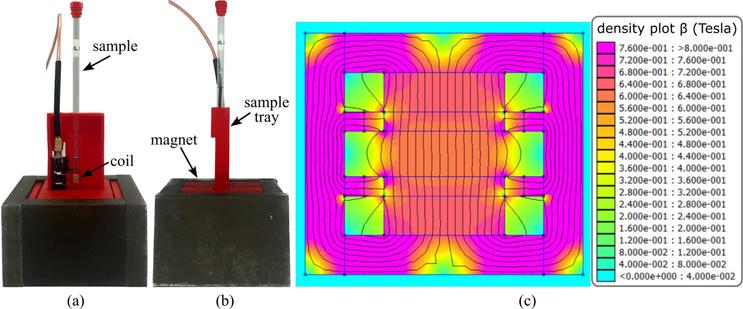

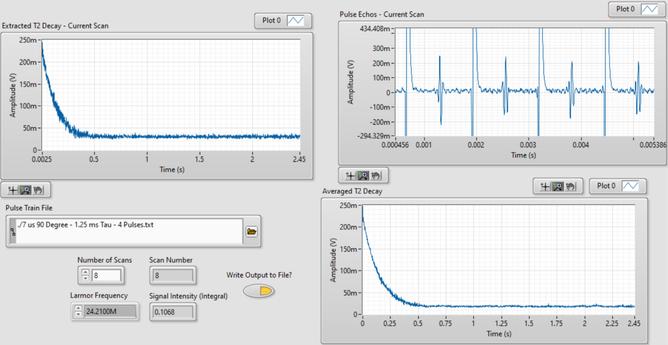

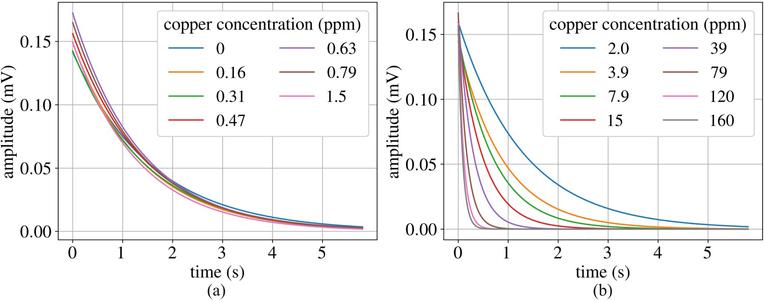

#cNMR: #OpenSource compact time-domain hydrogen (1H) #NMR system for field deployment:

-based on a 0.5 T permanent magnet

-emphasizes relaxation times rather than chemical shifts, enabling material property analysis without large magnets or complex spectral processing

-requires #LabVIEW

Paper: https://doi.org/10.1016/j.ohx.2025.e00651

GitHub: https://github.com/ARTS-Laboratory/Compact-NMR

#DIYbio #DIYchem #chemistry #lab #instruments

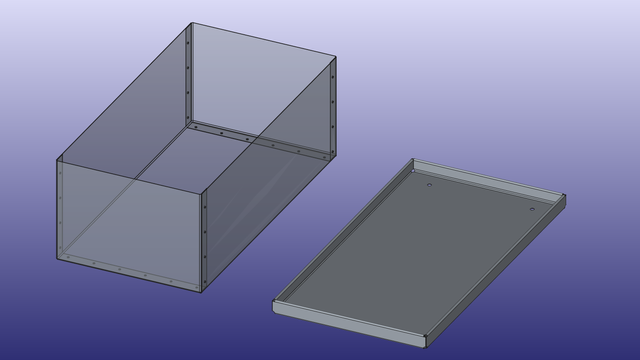

@FreeCAD And it's done!

@FreeCAD And of course I am making TechDraw drawings for each part!

@FreeCAD Working on a sheet metal box for protecting some delicate equipment today!

I finally published the repo for the rust CANOpen stack I've been working on, and wrote a post about it:

https://jeffmcbride.net/blog/2025/06/05/introducing-zencan/

It's still woefully incomplete, and needs a lot more contact with real problems to find the issues, and then I can decide if this is a good idea or a huge waste of time :).

I have never actually published a crate before, and soon I will publish 5!

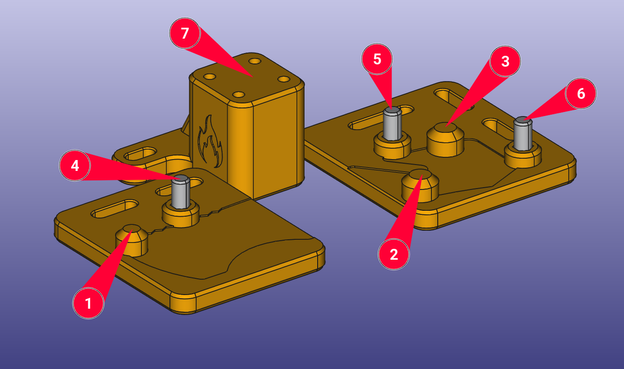

@M4x Here is a really good resource on workholding fixtures: https://www.carrlane.com/engineering-resources/fixture-design-principles/locating-clamping-principles

@M4x Roughly speaking:

1, 2, 3: Planar location of the bottom surface, restricting 5 degrees of freedom (DoF)

4, 5: Location of a side surface, restricting an additional 3 DoF

6: Restricting one more axial DoF such that the part is now exactly constrained

7: Mount for a toggle clamp that fixes the remaining 3 DoF to hold the part in position.

@M4x Ah, unfortunately not! I only put the CAD image in there because I never took pics of the real setup... :(

It's a 3-2-1 locating setup. At the bottom of this section I elaborate about this approach a bit more: https://blog.rahix.de/cnc-adhesive-applicator/#w1-infeed-and-egress-of-process-materials

@3dprinting I've always wanted to make a drill bit stop to make holes with controlled depth. Since I need to drill 37 15mm deep holes for the FilaBilly Humidor's rack ends, and the screws are supposed to arrive today, today is the day to actually make one.

The bit is centered between four flexible arms (PETG). The drill depth is set by how far I insert the bit into the chuck. This is another @rahix inspired design-for-printing thing.

🧵 41/N

Fused Filament Design Addon

A short while ago we posted here about an excellent article by @rahix describing some really interesting and useful design approaches for fused filament style 3D printing. If you haven't checked out that article it's really worth a read.

Brilliantly Rahix has worked on some macros which make it trivial to apply some of the excellent design techniques to your FreeCAD project.

https://blog.freecad.org/2025/05/23/fused-filament-design-addon/

#Addon

@HuK Does https://wiki.freecad.org/Spreadsheet_AlignLeft not do this?

@kbob Very nice, thanks so much! Immediately printed a few :)

I think there would be value in publishing some of the common sizes as pre-exported files on Printables, if you feel like doing that. Would make it easier for others to adopt the design without needing software/git/OpenSCAD knowledge.

Finally had the time to take some of the topics from my blog post about design for #3Dprinting and make them into a proper #FreeCAD addon!

You can download "FusedFilamentDesign" from the FreeCAD addon manager.

Also check it out here: https://github.com/rahix/FusedFilamentDesign

(This addon also integrates the macros I mentioned here a few weeks ago)

@josyb I do suggest using PETG V0 in the printing parameters table at the bottom of the description :)

@mcdanlj The semicircle ribs actually print decently in a horizontal orientation as well, as long as you rotate them so one rib is on the bottom.

I think chords will become "problematic" on larger thread sizes, where they may provide too much engagement again. For smaller sizes, I like the idea, although at that point screwing directly into a hexagon or even square hole will probably work equally well. Will also experiment more with this now that there's discussion about it! :D

@natlampen @infosecdj yes, that's the same method :)

@infosecdj like most plastic threads, torque is not a reliable indicator and they strip very easily. the smaller the thread, the worse it gets. for M5 and up, you can somewhat feel a torque difference after screw head contact, but i wouldn't rely on it either.

the usual approach is driving the screw until head contact and then for an additional fixed angle that doesn't stress the threads too much...