How 3D Printing Works: The Revolutionary Layer-by-Layer Manufacturing Process Explained

1,987 words, 11 minutes read time.

HELLO3D 3D Printer Filament,PLA Plus Filament 1.75mmAmazon Affiliate Link

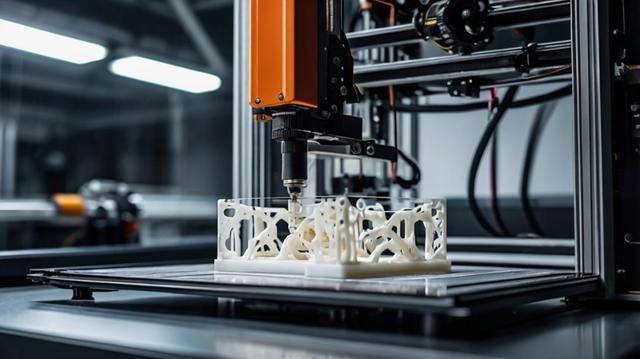

The world of manufacturing has undergone a revolutionary transformation with the advent of 3D printing. Once thought to be the realm of high-tech laboratories and research institutions, 3D printing has become an accessible and practical tool used by hobbyists, engineers, designers, and manufacturers alike. But how does this fascinating technology actually work? Why has it garnered so much attention and what makes it so appealing? In this article, we’ll explore the science behind 3D printing, break down the layer-by-layer manufacturing process, and look at how 3D printing is changing industries from healthcare to aerospace.

What is 3D Printing?

3D printing, also known as additive manufacturing, is the process of creating three-dimensional objects from a digital file. Unlike traditional manufacturing methods, which typically involve cutting or shaping material, 3D printing adds material layer by layer to build up an object. This method allows for incredible flexibility in design, as the process can create intricate and complex structures that would be impossible or too expensive to produce using conventional techniques.

At the core of 3D printing is a digital model. Using specialized software, designers create a virtual representation of an object, which is then converted into instructions that a 3D printer can follow. These instructions dictate the exact movements and material deposition required to fabricate the object. The printer follows these commands, laying down layers of material that harden or fuse together to create a solid piece.

The Science Behind 3D Printing

The beauty of 3D printing lies in its simplicity and precision. The process begins with a digital 3D model, often created using Computer-Aided Design (CAD) software. This model is then “sliced” into thin horizontal layers by slicing software, each representing a thin cross-section of the final object. The printer follows these slices to build the object layer by layer.

When a 3D printer is turned on, it uses specific materials (such as plastic, metal, or resin) to create an object. For most common desktop 3D printers, materials like PLA (Polylactic Acid) and ABS (Acrylonitrile Butadiene Styrene) are used. These thermoplastics are heated to a molten state and extruded through a nozzle. The nozzle moves according to the instructions provided by the software, precisely depositing material layer by layer. As each layer cools, it bonds to the previous layer, eventually creating a solid object.

The concept of “additive manufacturing” means that material is only added where it’s needed, rather than being removed like in traditional subtractive manufacturing (think CNC machines or milling). This results in less material waste, making 3D printing more environmentally friendly compared to conventional methods.

Types of 3D Printing Technologies

There are several different 3D printing technologies, each with its own unique process for creating objects. These technologies vary in terms of the materials they use, the speed of printing, and the level of detail they can achieve.

Fused Deposition Modeling (FDM) is perhaps the most well-known and widely used 3D printing technology. It works by extruding molten thermoplastic filament through a heated nozzle, which builds up the object layer by layer. FDM is commonly used for prototypes and small-scale production of plastic parts.

Stereolithography (SLA) is another popular 3D printing method that uses ultraviolet (UV) light to cure liquid resin, layer by layer. SLA is capable of producing highly detailed prints with smooth surfaces, making it ideal for creating intricate models and parts that require fine details.

Selective Laser Sintering (SLS) is a 3D printing method that uses a high-powered laser to fuse particles of powder (often nylon, metal, or ceramic) together. SLS printers can create complex and durable parts, especially in industries like aerospace and automotive manufacturing.

Other technologies, such as Digital Light Processing (DLP) and Electron Beam Melting (EBM), work in similar ways but use different light sources or methods for material fusion. Each of these methods offers advantages depending on the specific application and material requirements.

Materials Used in 3D Printing

The choice of material plays a crucial role in the success of a 3D printed object. While plastic materials like PLA and ABS dominate the market, there is an ever-growing range of materials being developed to cater to different industries and applications.

Thermoplastics are the most commonly used materials in 3D printing. PLA, a biodegradable plastic made from renewable resources, is often used for prototypes and educational projects. ABS, on the other hand, is a more durable and heat-resistant plastic commonly used for more robust applications, such as automotive or consumer goods.

For industrial applications, metal 3D printing has seen rapid growth. Materials like titanium, stainless steel, and aluminum are used in additive manufacturing to produce strong, lightweight parts. This is particularly useful in industries such as aerospace, where the demand for strong but lightweight components is high.

Resins are another material category in 3D printing. These materials are used with SLA and DLP printers and can be tailored for specific properties like flexibility, strength, or transparency. In medical and dental applications, biocompatible resins are used to create implants, dental crowns, and prosthetics.

One of the most exciting advances in 3D printing is the use of bio-printing, where living cells are used as the “ink” to print tissues and organs. While this field is still in its early stages, researchers are hopeful that 3D printing could revolutionize medicine by allowing for the creation of custom tissues and, eventually, organs for transplantation.

The Layer-by-Layer Process

The process of creating a 3D printed object starts with the creation of a digital file. Once the model is ready, slicing software divides it into thin horizontal layers. These layers are the key to how 3D printing works: the printer builds each layer on top of the one beneath it, gradually forming the complete object.

The key to the layer-by-layer process is precision. As the 3D printer deposits material, it does so with incredible accuracy, ensuring that each layer adheres perfectly to the one before it. This precision allows for the creation of highly detailed objects with complex geometries that would be impossible to achieve through traditional manufacturing.

In addition to precision, the layer-by-layer process also offers flexibility. Since the printer builds up an object from the bottom up, it can create intricate internal structures that are impossible to achieve through traditional molding or casting techniques. This is particularly useful for industries that require lightweight yet strong components, such as aerospace or automotive manufacturing.

The Role of Software in 3D Printing

The software used in 3D printing is just as important as the hardware. Computer-Aided Design (CAD) software is used to create the 3D model of the object, while slicing software breaks that model down into layers that the 3D printer can understand. These files are then sent to the printer, which interprets the instructions and begins the manufacturing process.

In addition to CAD and slicing software, calibration and print settings play a significant role in the final quality of the 3D print. Factors such as print speed, temperature, and layer height all need to be fine-tuned to achieve the best results. For example, a higher layer height will speed up the printing process but can result in less detail and rougher surfaces. A lower layer height, on the other hand, will produce finer detail but can significantly slow down the process.

The advancements in software also include the development of specialized programs that cater to specific industries. For example, in the medical field, software has been developed to help doctors design custom prosthetics and implants based on a patient’s unique anatomy.

Advantages of 3D Printing

One of the biggest advantages of 3D printing is its ability to create custom, one-of-a-kind objects. Since 3D printing is based on digital files, it’s easy to modify designs and produce a single item without the need for expensive molds or tooling. This flexibility makes 3D printing an ideal choice for rapid prototyping and custom manufacturing.

Another key advantage is the speed of production. In many cases, 3D printing can produce objects faster than traditional manufacturing methods. This is particularly important in industries where time-to-market is critical. 3D printing can also reduce the cost of producing small batches of parts, which is often too expensive using traditional methods like injection molding.

The precision and accuracy of 3D printing also open up new possibilities in design. Complex geometries that would be difficult or impossible to create using traditional manufacturing techniques can be produced easily with 3D printing. This has been a game-changer in fields like aerospace, where lightweight, strong, and intricate components are essential.

Challenges and Limitations of 3D Printing

Despite its many advantages, 3D printing does have some challenges. One of the most significant limitations is the materials that can be used. While there has been tremendous growth in the variety of materials available for 3D printing, it is still not possible to print every material in every application. For example, 3D printed metal parts, while incredibly strong, can be expensive and may not be suitable for all industrial applications.

Another challenge is the size of objects that can be printed. Most consumer-grade 3D printers are limited in terms of print size, making it difficult to produce large parts or objects. However, industrial 3D printers are capable of printing much larger objects, although these machines can be costly.

Finally, print speed and accuracy can also pose challenges. While 3D printing can be faster than traditional manufacturing in some cases, the process is still slower than other methods for mass production. Additionally, the layer-by-layer approach may result in visible lines or imperfections, depending on the quality of the printer and settings used.

The Future of 3D Printing

Looking ahead, the future of 3D printing is incredibly exciting. As technology continues to improve, 3D printers will become faster, more accurate, and more versatile. The development of new materials, including more advanced metals and even bio-materials, will expand the possibilities for 3D printing across industries.

In the medical field, we may see the ability to print functional organs and tissues in the not-too-distant future. In aerospace and automotive manufacturing, 3D printing will continue to play a major role in reducing weight and increasing efficiency. And in the consumer world, 3D printing will increasingly become a tool for creating custom products and parts.

With the rise of artificial intelligence and machine learning, 3D printing will become even more advanced. We may soon see 3D printers that can autonomously adjust settings or improve their own accuracy over time, further improving the process.

Conclusion

In conclusion, 3D printing is changing the way we think about manufacturing. By using a layer-by-layer approach to building objects, 3D printers offer unparalleled flexibility, precision, and customization. While there are still challenges to overcome, the possibilities for 3D printing are endless. Whether you’re a hobbyist, a designer, or an engineer, the impact of 3D printing will continue to grow, revolutionizing industries and everyday life.

If you’re passionate about 3D printing and want to stay updated on the latest advancements and insights, be sure to subscribe to our newsletter or leave a comment to join the conversation. Let’s keep exploring the world of 3D printing together!

D. Bryan King

Sources

- Smithsonian: How 3D Printing Works

- Explain That Stuff: 3D Printing

- CNBC: What Is 3D Printing?

- Live Science: What Is 3D Printing?

- Forbes: 10 Examples of How 3D Printing is Changing Manufacturing

- Engineering.com: The Basics of 3D Printing

- HowStuffWorks: How 3D Printing Works

- 3D Natives: What is 3D Printing?

- ScienceDirect: 3D Printing

- Additive Manufacturing Media: What Is Additive Manufacturing?

- 3D Printing Media Network: Types of 3D Printing

- The Verge: The Future of 3D Printing Materials

- Materials Today: 3D Printing

- Digital Trends: What is 3D Printing?

- Autoweek: 3D Printing in the Auto Industry

Disclaimer:

The views and opinions expressed in this post are solely those of the author. The information provided is based on personal research, experience, and understanding of the subject matter at the time of writing. Readers should consult relevant experts or authorities for specific guidance related to their unique situations.

Related Posts

#3DPrintedParts #3DPrintedPrototypes #3DPrinterSoftware #3DPrinterTypes #3DPrinting #3DPrintingAdvantages #3DPrintingAndManufacturing #3DPrintingApplications #3DPrintingBenefits #3DPrintingChallenges #3DPrintingCostEffective #3DPrintingCustomParts #3DPrintingDesign #3DPrintingEducation #3DPrintingForDesigners #3DPrintingFuture #3DPrintingFuturePotential #3DPrintingInAerospace #3DPrintingInAutomotive #3DPrintingInHealthcare #3DPrintingIndustries #3DPrintingInnovations #3DPrintingLimitations #3DPrintingMaterials #3DPrintingProcess #3DPrintingSpeed #3DPrintingTechnologies #3DPrintingTechnologiesExplained #3DPrintingTrends #ABSPlastic #additiveManufacturing #advanced3DPrinting #AIIn3DPrinting #bioPrinting #CADSoftware #complexGeometryPrinting #custom3DPrinting #FDMTechnology #highTech3DPrinting #industrial3DPrinting #layerByLayerManufacturing #manufacturingWith3DPrinting #medical3DPrinting #metal3DPrinting #PLAPlastic #precisionIn3DPrinting #rapidPrototyping #resinPrinting #SLAPrinting #SLAVsFDM #slicingSoftware