Anyone going to the AIAA Scitech conference, Jan. 9-11 in Orlando? I'll be exhibiting - please stop by my booth and say Hi from Mastodon-land! #Aerospace #AIAASciTech #AdditiveManufacturing #Ceramic3DPrinting

#Ceramic3DPrinting

Undersea acoustic transducers can be made by 3D printing the piezoelectric ceramic components. Sonar for small UAV's is one potential application. Such a cool project!

#3DPrinting #Ceramic3DPrinting #AdditiveManufacturing #Lithoz

Interesting conversations happening around Lithoz' new quartz glass 3D printing material. (Having material datasheets before the article landed sure would have been nice, just saying!)

#Lithoz #Glassomer #Ceramic3DPrinting #3DPrinting #AdditiveManufacturing

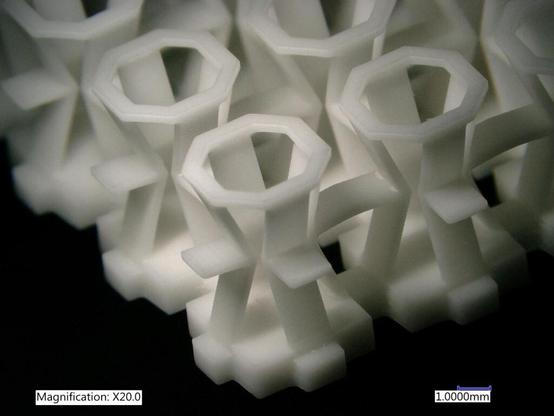

Here's what was running in the CeraFab S65 this morning. Our biggest shows, RAPID/TCT and Ceramics Expo, are held the same week this year (grrr), and we're scrambling to print extra copies of our favorite demo parts. These are double-walled Laval nozzles in aluminum oxide.

#Lithoz #3DPrinting #Ceramic3DPrinting

What I currently like thinking and learning about, and should spend more time on:

New ways to build the future,

#SustainableArchitecture #ConstructionAutomation #3DPrinting #Concrete3DPrinting #Ceramic3DPrinting #RammedEarth #BambooConstruction #OpenBIM #Biodome #ClimateEmulation #ClimateProofArchitecture #Robotics #Robots #Drones #OpenSourceEcology #HomeAutomation

New ways to create communities,

#CoopCities #StartupCities #RegenerativeVillages #CarFreeCity

4/8