#3DPrinting annoyance...

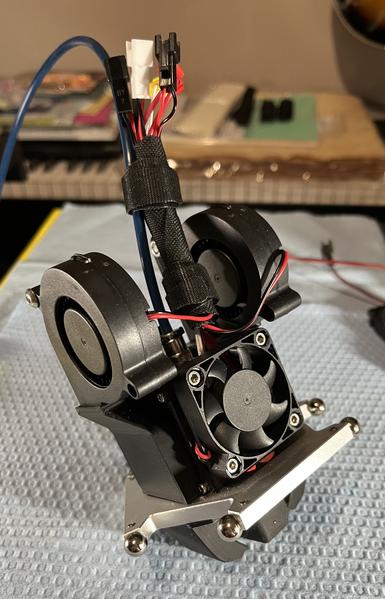

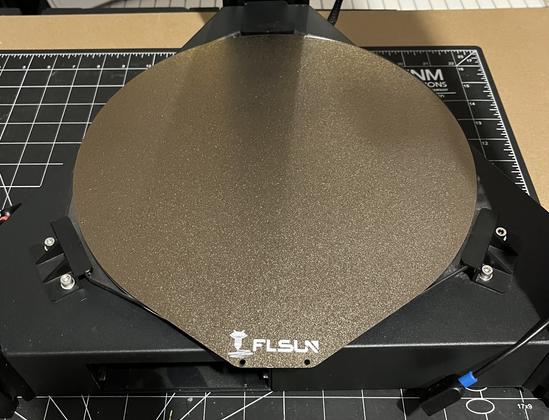

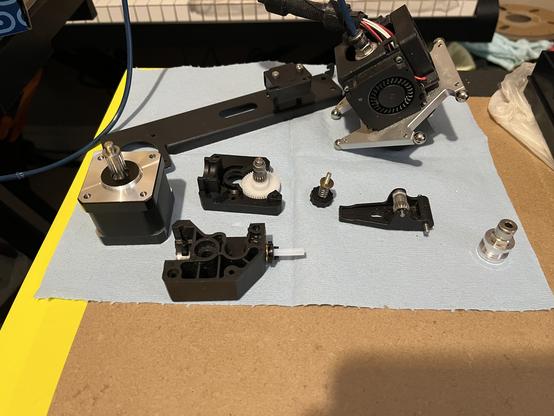

I have an #FLSun #V400 delta printer. A few upgrades, including to stock Klipper. I'm happy with it.

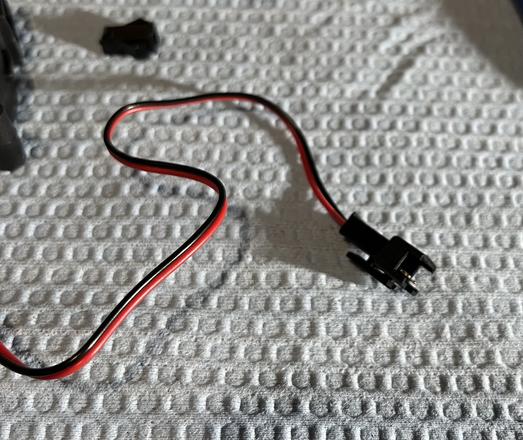

The issue: it's got a filament runout sensor up at the top of the print volume, right after the filament comes down through the top compartment of the printer, which houses the MCU and stepper motors. That works fine for detecting the end of a reel of filament.

But it's basically useless for detecting a filament break, because every break I've had has been between the sensor and the effector/hotend. The sensor happily indicates "filament good" while the hotend uses the remaining ~50cm of filament and then continues to print nothing, while cooking the leftover plastic in the hotend.

What do others do about this? Should I be moving the runout sensor to the effector, just on top of the extruder? Or I've seen what appear to be fancier sensors that detect filament movement, rather than being just a simple presence switch. Anyone have any experience with those?

I appreciate any thoughts from the more-experienced printers in the fedi. Thanks!