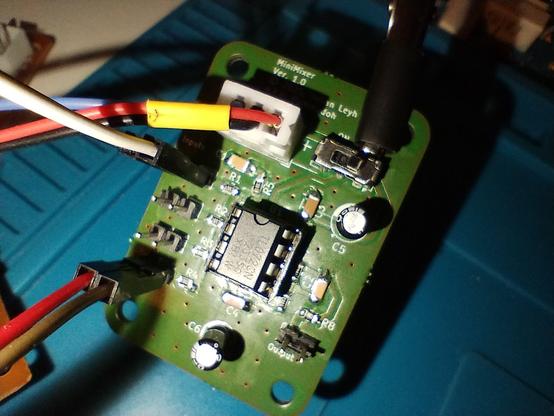

Finished #soldering. What I learned so far: l should clean between soldering #SMD components and #throughhole ones. I should leave enough space between the SMD components. I also dislike 0806 #resistors, better get some in 1206 size. The #capacitors were okay.

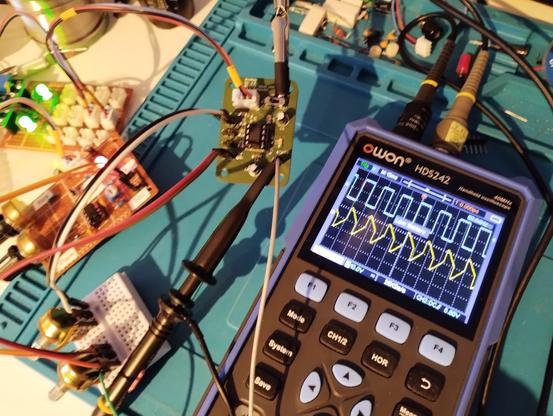

I tried it out with a square and a triangle wave as two inputs, connected through #potentiometers on a mini #breadboard and looked at the #oscilloscope

#diyelectronics #electronics #diysynth

#ThroughHole

Soldering, Up Close and Personal https://hackaday.com/2024/09/14/soldering-up-close-and-personal/ #throughhole #inspection #microscope #MiscHacks #Keyence #solder #tssop #bga #qfn #smd

house with a hole in it

#Surreal #EclecticHouse #ThroughHole #FoundObjectArchitecture #CrackedWalls #TurquoiseDoor #CircularWindows #Pool #UniqueDesign #ArtisticDetails

#Img2img #AiArt #AiArtists #StableDiffusion #AiArtCommunity

want-get-have: https://aieris.art/featured/house-with-a-hole-in-it-eris-and-ai.html

Off-Grid Radio Also Repairable Off-Grid https://hackaday.com/2023/08/19/off-grid-radio-also-repairable-off-grid/ #partsdrawer #throughhole #RadioHacks #atmega328p #lowpower #amateur #arduino #radio #scamp #ham #QRP

Hackaday Links: February 20, 2022

Sounds like somebody had a really bad day at work, as Western Digital reports that "factory contamination" caused a batch of flash memory chips to be spoiled. How much, you ask? Oh, only about 7 billion gigabytes! For those of you fond of SI prefixes, that's 7 exabytes of storage; to put that into perspective, it's seven times what Google used for Gmail storage in 2012, and enough to store approximately 1.69 trillion copies of Project Gutenberg's ASCII King James Version Bible. Very few details were available other than the unspecified contamination of two factories, but this stands poised to cause problems with everything from flash drives to phones to SSDs, and will probably only worsen the ongoing chip shortage. And while we hate to be cynical, it'll probably be prudent to watch out for any "too good to be true" deals on memory that pop up on eBay and Ali in the coming months.

Speaking of broken stuff, we came across a site called FailScout, which purports to be "a crowdsourced database of broken and worn-out products." The idea apparently is to document cases of what appears to be either systematic manufacturing defects, engineering problems, or outright planned obsolescence. The goal of this is ostensibly to hold manufacturers accountable for their products, but we can see how this could just devolve into a morass of ax-grinding by people who have unreasonable expectations about how long products should last. Yes, pretty much everything we buy is subject to "value engineering" decisions in terms of materials and designs, and some of that will no doubt send products to the landfill long before their time. But when someone is complaining about broken five-year-old flip-flops, we think we'll take a hard pass on this one.

For the numerically obsessive among us, a momentous day is approaching. This coming Tuesday will be "Twos Day," when everyone's calendar will show 2/22/22 (or 22/2/22, if you're so inclined) all day. And for a special treat, if you want to add to the symmetry and don't mind getting up early, or staying up late, you can watch the clock flip to 2:22:22 on the appointed day. If this excites you as much as watching an odometer flip over, you'll probably want to visit this interesting Palindrome Date calculator, and see how long it'll be before some other interesting sequence of numbers will be encoded in the date.

While trolling through Hackaday.io the other day, we happened upon a project that looks interesting: a miniature selective soldering machine. Until we saw this, we hadn't even wondered how mixed through-hole and SMD boards are assembled; selective soldering seems to be the answer. It seems to be a very localized version of wave soldering. Instead of using a large tank that covers the entire underside of a board, the molten solder is pumped into a special nozzle to form a tiny fountain. This little solder volcano is moved around the board to all the through-hole leads that need soldering, and it's a very satisfying process to watch.

And finally, because the world is crying out for a car with 80's styling and a 21st-century electric drivetrain, it looks like DeLorean is trying to make another go of it. Maybe it's the nostalgia of the approaching 40th anniversary of the first installment of the Back to the Future trilogy, or maybe it's just because they can, but whatever the reason, the hype machine is already rolling, albeit with nothing but a silhouette shot of the iconic and never-practical gullwing doors opening. And even though it's electric, we wouldn't count on a 1.21-gigawatt battery. Or a Mr. Fusion.

#hackadaycolumns #hackadaylinks #slider #chipshortage #delorean #flash #memory #nand #palindrome #plannedobsolescence #selectivesoldering #soldering #throughhole #twosday #westerndigital

Solder Bridges Aid Desoldering

As our own Elliot Williams laid out, many people think that soldering is a key skill for electronics, but we don't as often think about desoldering. Even if you are perfect in your technique, there's always the chance you'll put in a bad part or have a part fail later and it will need replacement. [Robert] has a short video showing his method for removing through-hole components and you can see it below.

This isn't the first time we've seen it, of course. In fact, it is very much like using hot air, although it doesn't require hot air, just extra solder and a regular iron. Of course, if we knew that connector was bad, we'd have been tempted to cut each pin apart and remove them one at a time. Heating a joint and then slamming your hand on the bench can work wonders.

We always think desoldering pumps are a good idea, but the electric ones tend to be anemic. The ones with the springs are usually better, but still have limitations. In the end, we'll stick with using hot air, but if all you have is an iron, this method is worth checking out. You might also be interested in the needle method.

Modified 3D-Printer Solders Through-Hole Components

Surface-mount technology has been a fantastic force multiplier for electronics in general and for hobbyists in particular. But sometimes you've got no choice but to use through-hole components, meaning that even if you can take advantage of SMDs for most of the design, you still might need to spend a little time with soldering iron in hand. Or not, if you've got a spare 3D printer lying around.

All we've got here is a fairly brief video from [hydrosys4], so there aren't a lot of build details. But it's pretty clear what's going on here. Starting with what looks like a Longer LK4 printer, [hydrosys4] added a bracket to hold a soldering iron, and a guide for solder wire. The solder is handled by a more-or-less standard extruder, which feeds it into the joint once it's heated by the iron. The secret sauce here is probably the fixturing, with 3D-printed jigs that hold the through-hole connectors in a pins-up orientation on the bed of the printer. With the PCB sitting on top of the connectors, it's just a matter of teaching the X-Y-Z position of each joint, applying heat, and advancing the solder with the extruder.

The video below shows it in action at high speed; we slowed it down to 25% to get an idea of how it is in reality, and while it might not be fast, it's precise and it doesn't get tired. It may not have much application for one-off boards, but if you're manufacturing small PCB runs, it's a genius solution. We've seen similar solder bots before, but hats off to [hydrosys4] for keeping this one simple.

Thanks to [Arturo] for the tip!

#3dprinterhacks #extruder #fixturing #gantry #smt #solderbot #soldering #throughhole

Tape Cutter Makes Short Work Of Through-Hole Resistor Reels

As the world of electronics makes its inexorable movement from through-hole parts to surface-mount, it's easy to forget about the humble wire-ended resistor. But a stack of them is still a very useful resource for any experimenter, and most of us probably have a bunch of them with their accompanying twin strips of tape. We're entranced by [Sandeep]'s automated resistor tape cutting machine, which uses a fearsome looking pair of motorized knives to slice the tape into predetermined lengths.

At its heart is an Arduino and a set of stepper drivers, and it uses a PCB that he's designed as a multipurpose board for motor-based projects. One motor advances the reel of resistors, while the other two operate those knives that simultaneously slice the two tapes. The whole is held in a wooden frame with 3D-printed parts, and control is through a touch screen. This feels more like an industrial machine than a maker project, and as can be seen in the video below, it makes short work of those tapes. Full details can be found on his website, including code.

We've not had so many through hole tape cutters, but we've seen at least one SMD cutter.