It’s Printable, It’s Programmable, It’s E. coli

Well, whaddya know? It seems that E. coli, the bane of Romaine and spinach everywhere, has at least one practical use. Researchers at Harvard have created a kind of 3D-printable ink that is alive and made entirely of microbes produced by E. coli. Although this is not the first so-called living ink, it does hold the title of the first living ink that doesn't need any additional polymers to provide structure.

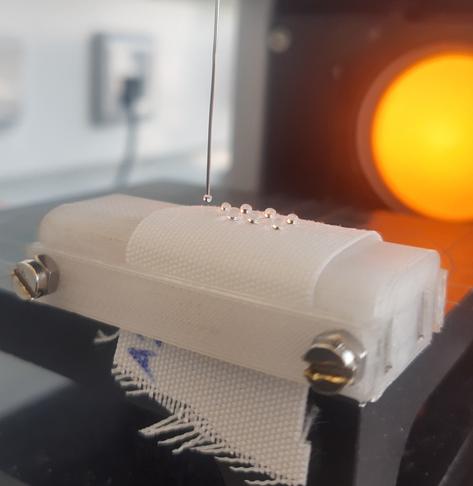

Passing the pillar test up to 16mm. Image via Nature

Because the ink is alive, it is technically programmable in the sense that it can self-assemble proteins into nanofibers, and further assemble those into nanofiber networks that comprise hydrogels.

One of the researchers compared the ink to a seed, which has everything it needs to eventually grow into a glorious tree. In this way, the ink could be used as a renewable building material both on Earth and in space. Though the ink does not continue to grow after being printed, the resulting structure would be a living system that could theoretically heal itself.

The ink creation process begins when the researchers induce genetically-engineered bacteria cultures to grow the ink, which is also made of living cells. The ink is then harvested and becomes gelatin-like, holding its shape well enough to go through a 3D printer. It even passes the bridging test, supporting its own weight between pillars placed up to 16 mm apart. (We'd like to see a Benchie.)

Microbial Mechanics

Is it weird to work with microbes? Not really. They are already a part of vitamins and some perfumes, and other types of microbes are out there maturing into biodegradable plastics. E. coli has been used before to create a hydrogel capable of growing and regeneration, but it wasn't viscous enough to pass through a printer. So they genetically engineered the E. coli to produce a natural polymer from fibrin, which is a blood-clotting polymer possessed by humans and animals alike. The polymer created by the bacteria is designed to link together into a network, which one researcher likened to a heavy-duty cargo net.

This all-microbe E. ink is still being developed. So far, it is already quite an improvement over what was viable only five years ago. Why 3D prints with E. coli? The ink showed promise as a drug delivery system, for example. In a test, the ink was shown to release an anti-cancer drug called azurin after being exposed to a certain chemical. One of those functions might be cleaning up the environment. In another test, the ink was proven to sequester the toxin BPA from its surroundings.

Though this all sounds great, the ink is still in development and has a way to go. For one thing, it doesn't withstand drying out, but that may not be an obstacle if the ink is combined with tissue engineering. However, if we're going to use it as a self-regenerating material for building habitats on Earth and in space, it will have to become more stable.

Via [New York Times]

#news #science #biopolymer #ecoli #fibrin #ink #microbes #microbialink #printablebacteria