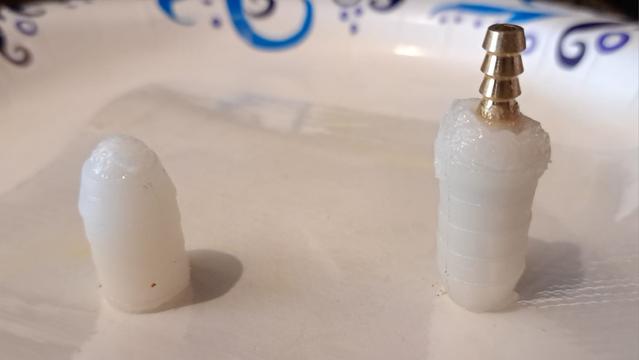

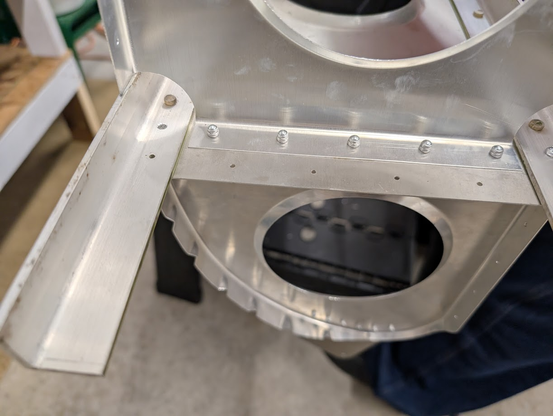

As I perform final assembly of various glider parts (landing gear, flight controls, etc.) I am replacing many temporary/keeper parts, such as nuts, and some bolts. (see photo)

The many silver-colored nuts (zinc plated) are ordinary hardware store parts. They are not locknuts.

The few gold colored nuts (cadmium plated?) have a small rounded top where a nylon insert has been added. These are nylon lock nuts...nylocks. Those are the parts I want for most final assembly tasks. (Landing gear locknuts will use cotter pins or safety wire. They withstand greater shock loads and nylocks are insufficient.)

Note that some of the bolts in the photo are threaded along the entire length. Those are not suitable for connecting parts that are subject to shear loads. Instead, you want a bolt with a smooth shank. I am checking every bolt to make sure I have the correct shank length.)

#AvGeek #Aviation #ElectricAircraft #ExperimentalAviation #Homebuilt #Glider #DIY #Procedures #Nuts #Bolts