Today I’ve advanced to a next level of 3D printing fan club.

Yesterday, when printing a part for my son’s base the printer went awry and messed it up. I’ve stoped it in the middle of printing. I’ve then tried a tiny few minute model, and it failed.

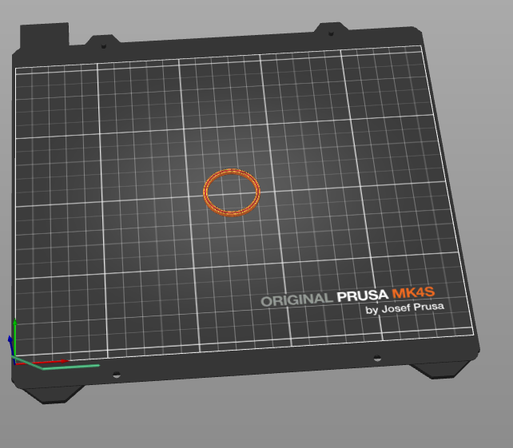

I’ve decided to run printer calibration and to my surprise it failed. I’ve rerun it 3 times with same result: Y-axis cannot be calibrated.

I’ve spend some time searching and it seemed that a Y-axis belt may be incorrectly fastened. I’ve used Prusa app to check it, but it seemed good.

I’ve been wondering what else may be wrong and had an “aha” moment and decided to check all screws. That’s how I’ve found out that the screws on this little piece have loosen themselves and were causing a slip when an engine was trying to push the printing bed really fast.

Now it works and I can go back and print the joints ;-)

#olsztyn #3dprinting #fatherhood #prusa #prusamk4