I covered all the theory and main functions of the code for my Arduino Euclidean Gate Sequencer in my previous post. In this one I look a little more at some hardware that hopefully lets me use this to actually control something useful!

- Part 1 covered all the theory and main functions of the code.

- Part 2 included some hardware suggestions for connecting it to other devices.

- Part 3 added a rotary encoder and I2C display and demonstrated by Arduino Clock Generator Shield PCB.

- Part 4 reimplements HAGIWO’s original with a few tweaks and updates.

Warning! I strongly recommend using old or second hand equipment for your experiments. I am not responsible for any damage to expensive instruments!

All of the key ideas along with a list of references for the main concepts used in this project were listed in my first post here: Arduino Euclidean Gate Sequencer.

If you are new to Arduino, see the Getting Started pages.

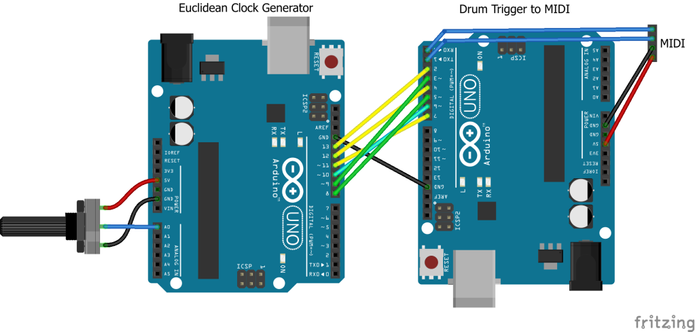

Experiment 1: Arduino to Arduino to MIDI

I could add MIDI functionality to my Euclidean clock generator, but instead opted to build a TRIGGER to MIDI converter using a second Arduino. This has several digital inputs setup to receive TRIGGER pulses and on reception will send out a preconfigured MIDI message.

The configuration is such that a NoteOn is sent for a specific drum on MIDI channel 10 which is typically used for percussion. Which drum corresponds to which input is configurable in the code.

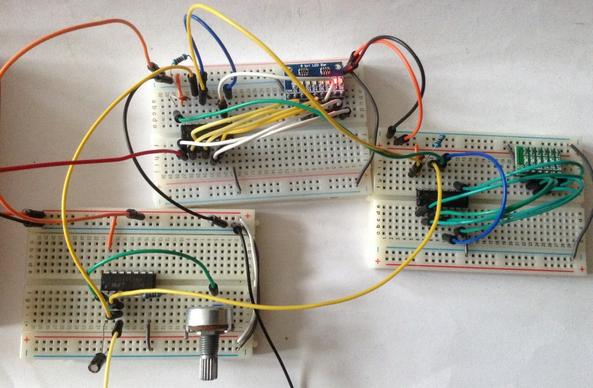

Full details of this so far can be found here: Arduino Drum Trigger to MIDI. This is how I connected them up and it seems to work pretty well.

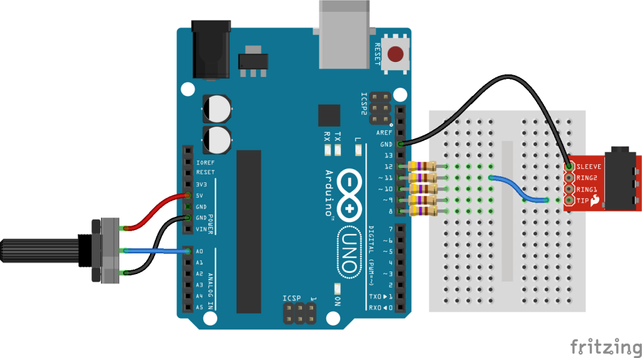

Arduino to GATE or TRIGGER Output

Here I’m setting up the board to be able to drive an external device.

As always, the standard warning applies – use second hand or disposable equipment for experiments. I am not responsible for damage to expensive instruments. Assess what I’m doing, decide for yourself how it will affect your equipment and then use at your own risk.

I’ve followed the design from HAGIWO’s GATE sequencer, which is detailed in full here: https://note.com/solder_state/n/n17c69afd484d

This recommends the following:

- All outputs clamped to the Arduino’s 5V and GND using BAT43 Schotky diodes.

- 470Ω resistor on the output to set an output impedance.

I’m wanting to plug this into my Korg Volca Sync In.

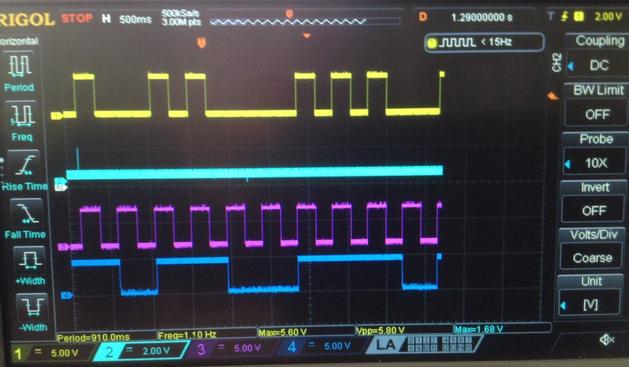

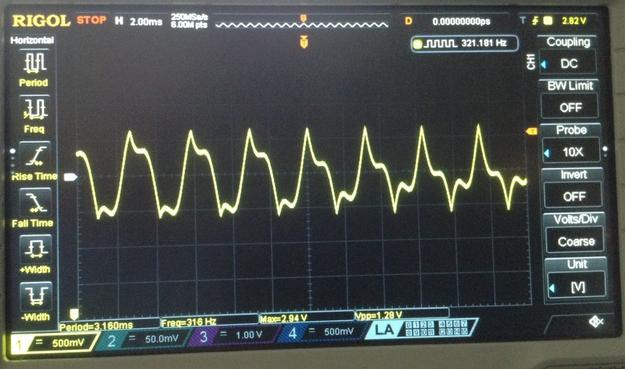

With an oscilloscope I examined the Sync Out signal and confirmed that it is a 5V pulse of 15mS. As I’m only plugging a 5V Arduino into the 5V accepting Korg, I’ve not bothered with the clamping diodes for my simple experiments, but if I build this up into a PCB then I’ll probably add them in to make it a little more universal.

The TRS jack is wired to be compatible with the Korg Volca Sync In port – i.e. using just the tip and shield. A stereo or mono 3.5mm jack to jack cable (as comes supplied with a Volca) can then be used to connect it up.

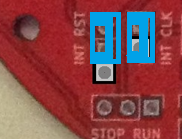

The blue jumper wire can be used to select which of the Euclidean clock outputs to use.

The code is built for TRIGGER mode, so each output is a single 10mS pulse. This is shorter than that produced by the Volcas but generally seems to work.

When first connected or when the tempo is changed I sometimes hear some spurious or irregular triggering, but once it has settled down it seems to work fine for my Volca Keys, Volca Modular, and Volca FM2.

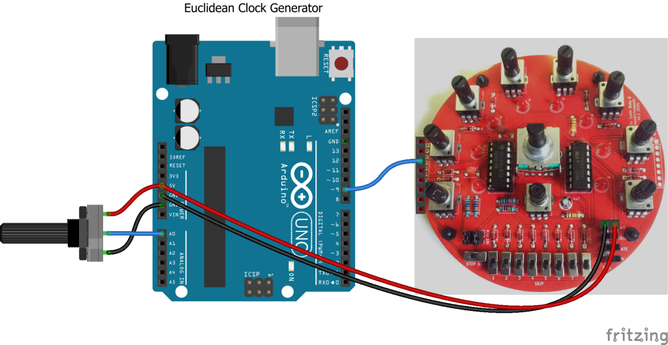

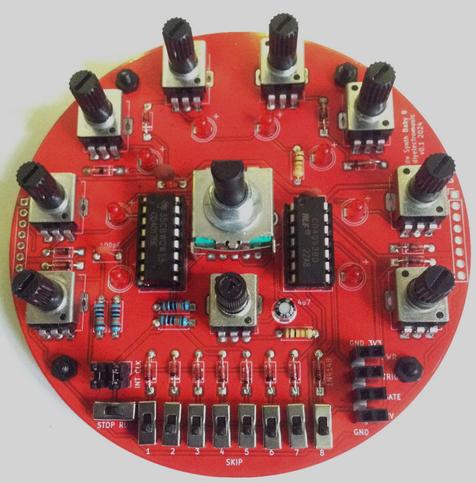

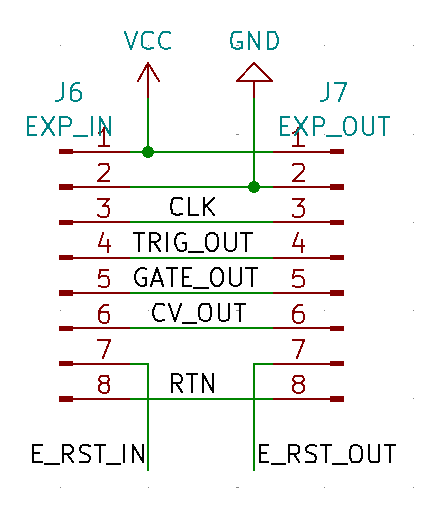

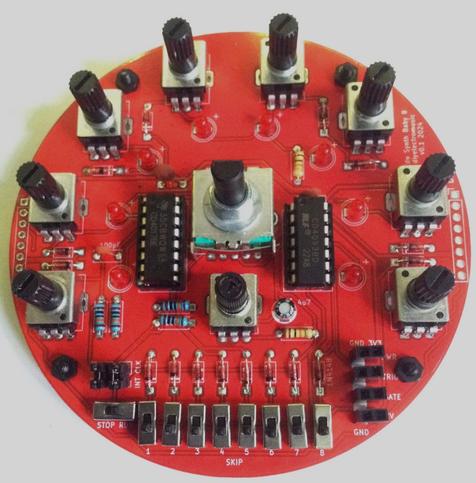

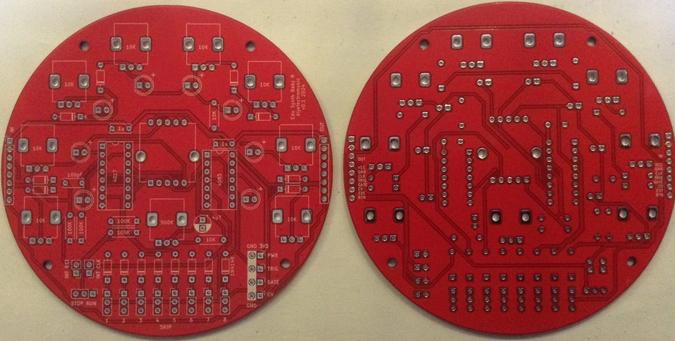

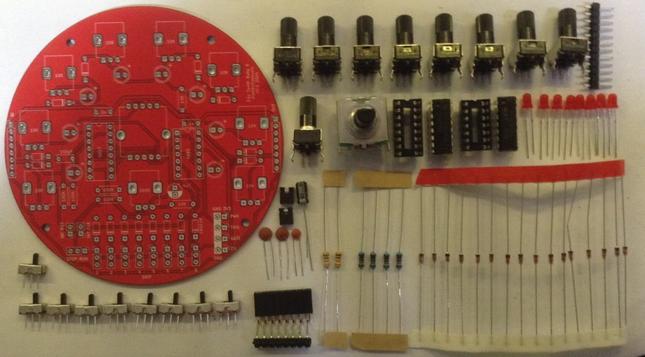

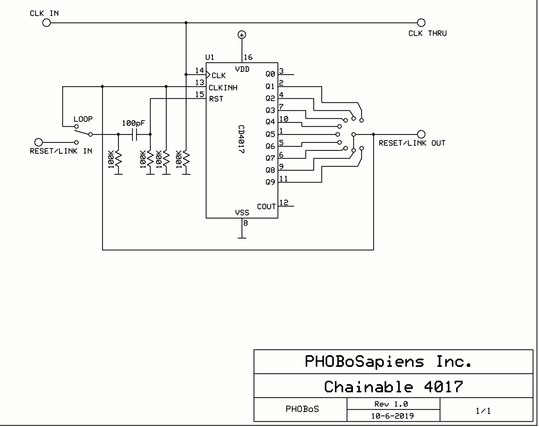

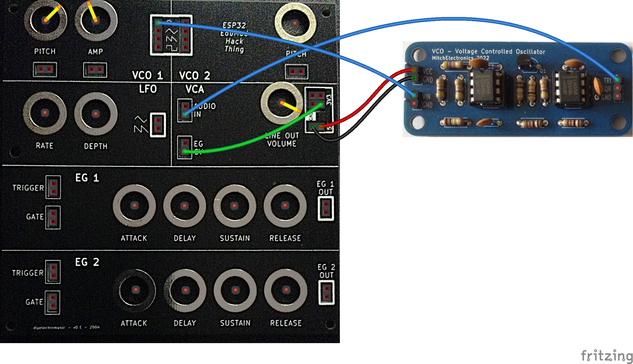

Arduino to ESP32 Synth Thing Baby8

The “Baby8” CV Step Sequencer has an option to be driven by an external clock. If the INT_CLK jumper is removed then it will trigger off whatever is plugged into the CLK header pin (third down from the top of the header).

This means that, assuming the Baby8 is powered off 5V, then any of the Arduino GPIO clock outputs (D8-D13) can be directly connected as shown below.

This is directly connecting the Arduino’s GPIO OUTPUT pins (the clock) to the Baby 8’s 4017 timer CLK pin. As in general terms directly connecting an OUTPUT to an INPUT is deemed an ok thing to do (INPUTs are high impedance as I understand things), i.e. the output of a microcontroller, 555 timer, or NAND oscillator and so on are often set up to drive the CLK pin directly, then connecting it directly to an Arduino GPIO OUTPUT should be fine.

It is also possible to drive the actual Educational DIY Synth Thing itself as it includes 5V tolerant GATE and TRIGGER inputs, but having a regular clock pulse with no pitch CV information is somewhat limited.

But using the Baby8 as shown above with the Synth Thing too should work fine, although if the Baby 8 is powered off 5V then the top of the potentiometer’s range will be slightly too high for the Synth Thing which will top-out at around 3V3. It won’t damage the Synth Thing as the CV inputs are clamped to the 0 and 3V3 power rails.

Closing Thoughts

Naturally getting the logic signal doing the right thing on a GPIO port is only part of the equation. That is only useful if it is able to control something else.

This post looked at some options, from the hacky “quick and dirty” versions through to what ought to be done to do things properly.

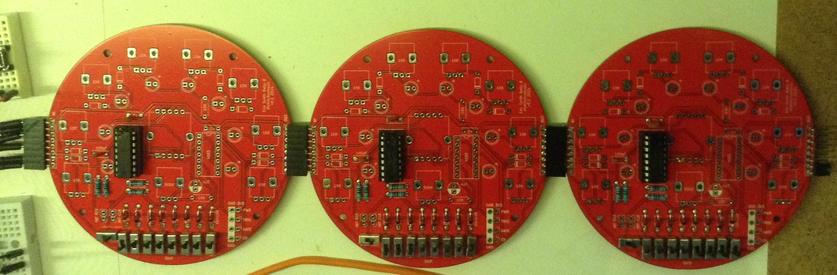

I’m still chewing over the idea of some kind of trigger shield or similar PCB.

Kevin

https://diyelectromusic.com/2024/10/07/arduino-euclidean-gate-sequencer-part-2/

#arduinoUno #baby8 #euclidean #gate #midi #stepSequence #synthThing