Hey #3dprinting community!

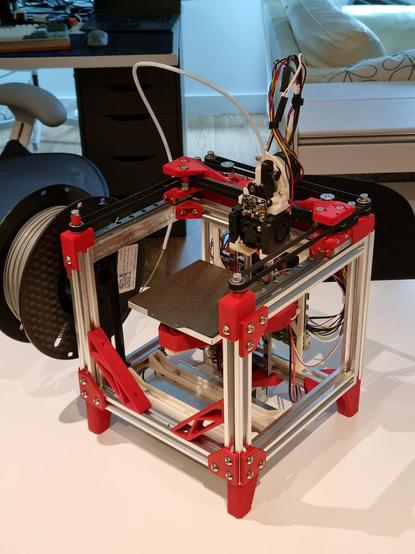

I'm running a sturdy #corexy printer I've build myself back in 2018. Currently, I'm thinking about replacing it. Since 2018, the market evolved and seems to come up with affordable quality builds, quality of life features, new capabilities (multicolor ...) and the need for less tinkering (I've kids now 😉). It seems like the more "integrated" systems don't play nice with my beloved #octoprint . Is it getting less relevant? What do you think?

#creality #BambuLab