Des « boulets de canon » solaires frappent Mars : MAVEN observe le “sputtering”, un mécanisme d’érosion atmosphérique accélérée. Une clé de sa déshydratation passée.

https://sante.journaldesfemmes.fr/quotidien/3230988-nasa-le-soleil-tire-des-boulets-de-canon-sur-mars/

#Space #NASA #Mars #MAVEN #SolarWind #AstroNews #Sputtering #ScienceMars #Heliophysics

#Sputtering

Visualization of rivers and streams starting at McKenzie River, Oregon and zooming out to Lower 48 States 🪐

#Current #EarthScience #Mars #Oceans #Physicaloceanography #River #Rivers/Streams #Sputtering

⏩ 1 new picture and 3 new videos from NASA (SVS) https://commons.wikimedia.org/wiki/Special:ListFiles?limit=8&user=OptimusPrimeBot&ilshowall=1&offset=20250601125852

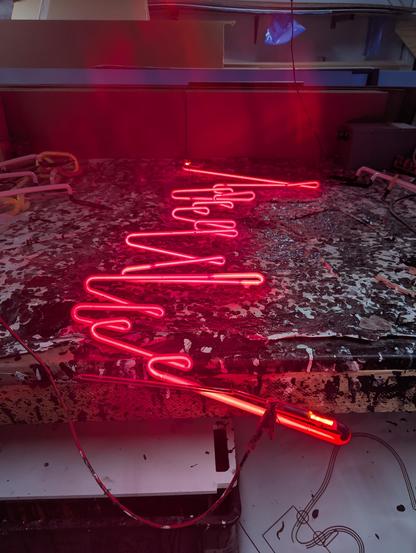

Got to fix another piece of neon to an "NYC Institution" today- Trash and Vaudville.

Although I have never actually been- I did find a photo of where the neon goes online- looks like near the back of the store.

This one was "natural" tube death from sputtered electrodes. They used super tiny electrodes, which run hot and flake off their metal from the electrons running into them. This also reduces the pressure in the tube leading to even more sputtering. Those old blackened shiny electrodes have been on and sputtered for awhile. Probably about a decade or two or even more.

I fixed it by replacing its electrodes, repumping it, and repainting. Took me one hour.

I replaced the electrodes for ones with the shells twice as big. Should be good for decades more. Fixing red neon tubes brings a strange satisfaction, especially when they are ruby red.

#nyc #neon #repair #repump #glass #sputtering #work #brooklyn #trash #vaudville #handmade #muranoglass

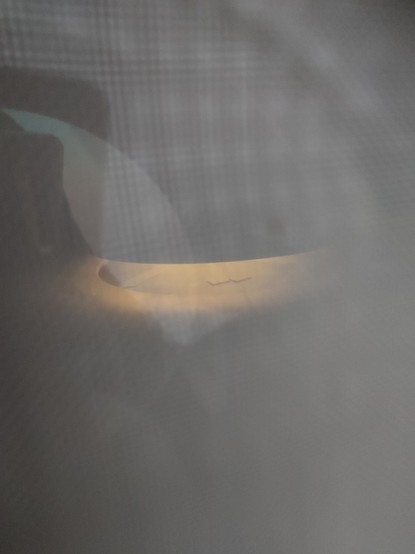

What you can see here is the glowing of the argon #plasma during a DC #sputtering process.

The argon ions inside the plasma are accelerated by a high voltage (multiple hundred volts) and collide with the metal target. These impacts throw out some atoms of the target, which then get deposited on the small substrates you can see at the bottom. That way you can create thin metal layers with just a few hundred nanometer thickness or less.

The Next-Generation of Memory Technology – New Material Shows Promise

Phase change memory is a type of nonvolatile memory that utilizes the capability of phase change materials (PCM) to transition between an amorphous state, where atoms are scattered, and a crystalline state, where atoms are closely aligned. This change produces a reversible electrical property that can be engineered to store and retrieve data.

https://scitechdaily.com/the-next-generation-of-memory-technology-new-material-shows-promise/ #memory #electronics #PhaseChange #data #Niobium #Telluride #NbTe4 #sputtering

This method offers a solution for those working on #QuantumTech hardware, as it presents a new alternative to chemical-based copper plating. The procedure is simple and efficient and leads to a uniform metal coating. #Sputtering

The magnetron-sputtered coating in our preprint did not show delamination from the glass substrate, even at a critical load of 60 N. This demonstrates the strong adhesion thanks to the unique surface structure created by the laser. #SurfaceEngineering

🤩Excited to share our latest preprint on #LaserAssisted Two-Step Glass Wafer Metallization! A simple & efficient solution for improved compatibility between glass & metallic films. #MaterialsScience

➡️ https://dx.doi.org/10.2139/ssrn.4343362

Our team at #Matfyz Charles University, #HiLASE Centre & #CVUT have collaborated to bring this innovation to life using laser microstructuring at ambient conditions. The result is a thick layer of the metal film with high adhesion strength & low surface roughness.

This method offers a solution for those working on #QuantumTech hardware, as it presents a new alternative to chemical-based copper plating. The procedure is simple and efficient and leads to well-defined grains and grain boundaries in the metal film. #Sputtering

The magnetron-sputtered coating in our preprint did not show delamination from the glass substrate, even at a critical load of 60 N. This demonstrates the strong adhesion of the metal film to the glass substrate, thanks to the unique surface structure created by the laser. #SurfaceEngineering

This method of glass metallization will be a game-changer for those in the field of high-frequency electronic devices. The preprint outlines a practical solution for the realization of glass-based circuit materials, offering a more cost-effective alternative to chemical-based copper plating.